Water Pump

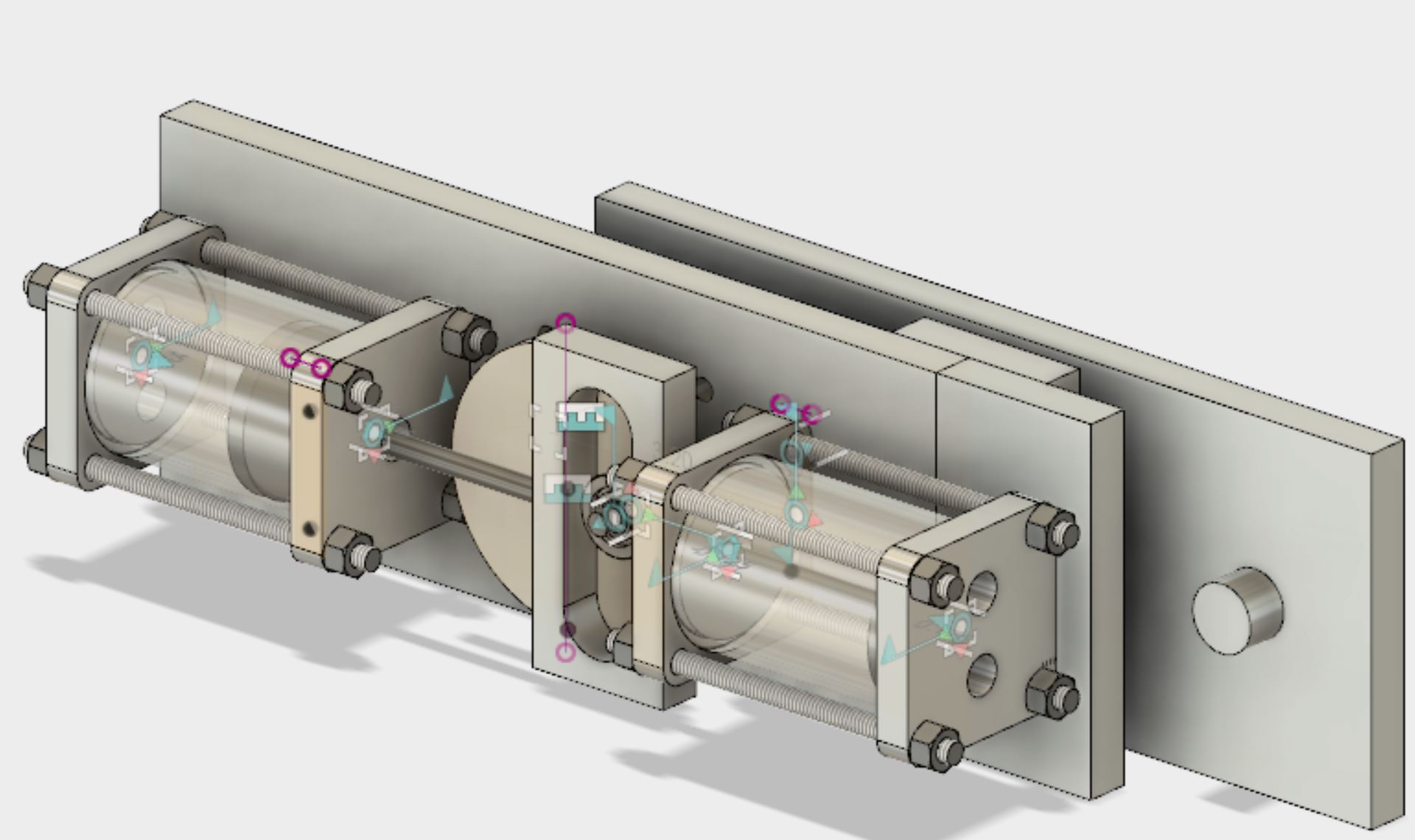

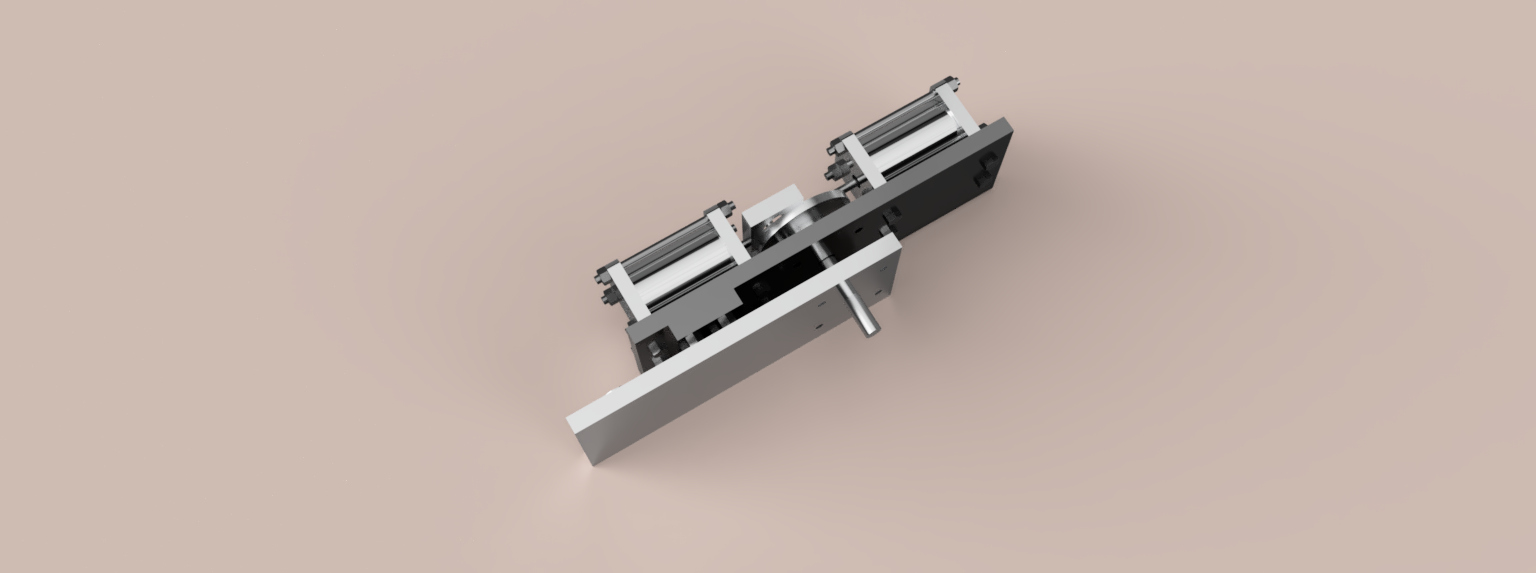

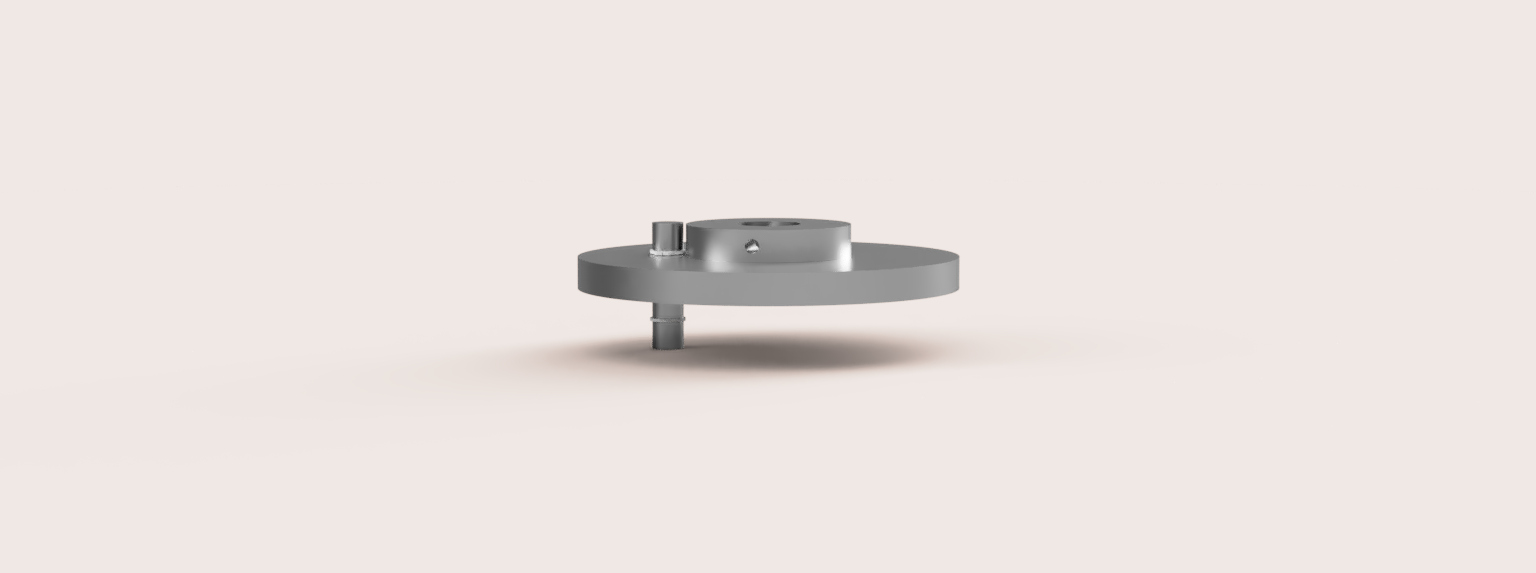

Our task was to make a pump that could move 1 liter of water per minute against gravity. We could use any pump type (piston, peristaltic, etc.) but had to fabricate it ourselves from aluminum stock and standard parts (o-rings, bearings, etc.) using a mill and lathe. Our group initially split up to research the pros and cons of the various feasible types and prepare an initial CAD design for the type we researched. I researched piston pumps, which we decided to use for their reliability and relatively simple fabrication. Specifically, we chose a two-cylinder reciprocating pump powered by a scotch yoke mechanism.

After adding more detail to and improving the CAD design, we assembled a BOM and bought the necessary materials. Then it was a relatively easy fabrication process except for the scotch yoke, which had to have its thickness substatially reduced with the lathe. After assembly and testing, we ended up with a pump that moved 5 L/min.

I really enjoyed this project because it was fun to do something hands-on, especially given that we were able to take it all the way from research and design to a finished and working pump that we could see in action. It was a very valuable experience from that perspective and also in terms of getting practice working with an engineering team in a practical environment that included things like formal BOMs, order forms, and cost estimates.