Project Overview

Our team designed and fabricated a two-cylinder reciprocating pump that exceeded the project requirements, delivering 5 liters per minute against gravity—five times the required flow rate.

Project Requirements

- Design and build a pump capable of moving 1 liter/minute against gravity

- Fabricate all key components from aluminum stock and standard parts

- Use machine tools (mill and lathe) for component manufacturing

- Document the complete engineering process from research to testing

- Optimize for reliability, efficiency, and manufacturability

This project provided a comprehensive engineering experience that spanned research, design, component selection, fabrication, assembly, and performance testing. Working through the entire product development lifecycle gave us valuable hands-on experience with both technical and project management skills.

Design & Engineering Process

Research & Pump Selection

Our team began by researching various pump technologies to determine the optimal design for our requirements. We evaluated several pump types including:

Piston Pumps

- Excellent reliability

- High pressure capability

- Relatively simple fabrication

- Good efficiency

Peristaltic Pumps

- Gentle fluid handling

- No fluid contamination

- Complex roller mechanisms

- Lower pressure capabilities

After evaluating the trade-offs, we selected a two-cylinder reciprocating piston pump design with a scotch yoke mechanism. This configuration offered the best combination of reliability, manufacturability, and performance for our application.

CAD Design & Optimization

Once we selected the pump type, we developed detailed CAD models to refine the design before fabrication. Key design considerations included:

- Piston Cylinder Ratio: Optimized for flow rate and pressure requirements

- Scotch Yoke Design: Ensured smooth reciprocating motion with minimal vibration

- Seal Selection: Chose appropriate O-rings for preventing leakage

- Material Selection: Selected aluminum for most components due to machinability and weight

- Assembly Considerations: Designed for ease of manufacturing and maintenance

The CAD modeling phase allowed us to identify potential issues and refine our design before moving to fabrication, saving time and materials in the manufacturing process.

Fabrication & Assembly

With our design finalized and a complete bill of materials prepared, we proceeded to the fabrication phase:

- Machined the aluminum components using a mill and lathe

- The scotch yoke mechanism required precision turning to achieve the necessary thickness

- Assembled the pump using standard fasteners, bearings, and O-rings

- Tested initial operation and made adjustments to ensure smooth movement

- Finalized the assembly with proper sealing to prevent leaks

Testing & Results

After assembly, we conducted thorough performance testing to evaluate our pump against the project requirements:

Required Flow Rate: 1 L/min

Achieved: 5 L/min

500% of required performance

Our pump significantly outperformed the project requirements, delivering five times the specified flow rate. This success validated our design choices and manufacturing precision.

Project Gallery

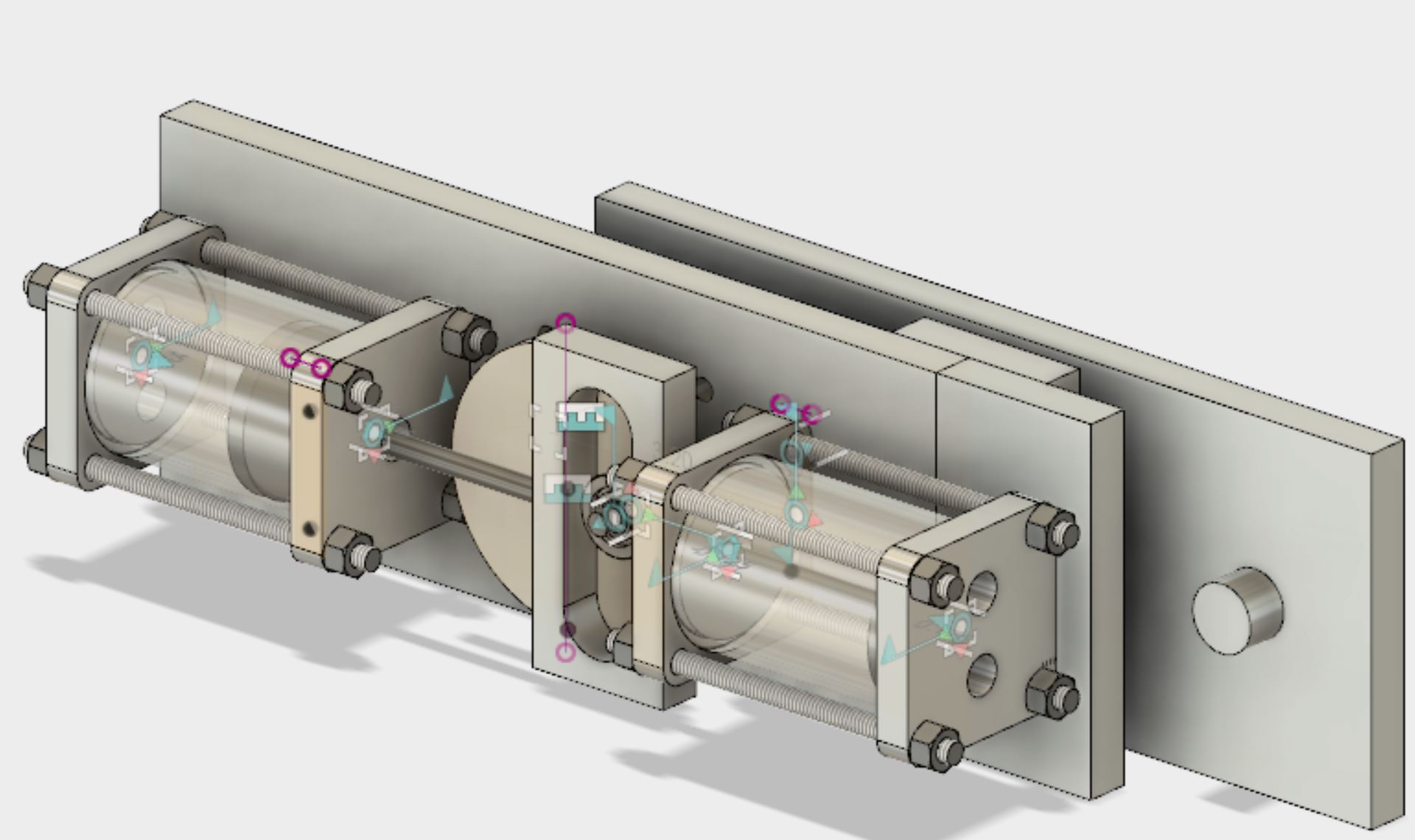

CAD Design

Initial computer-aided design showing the pump's core components and layout.

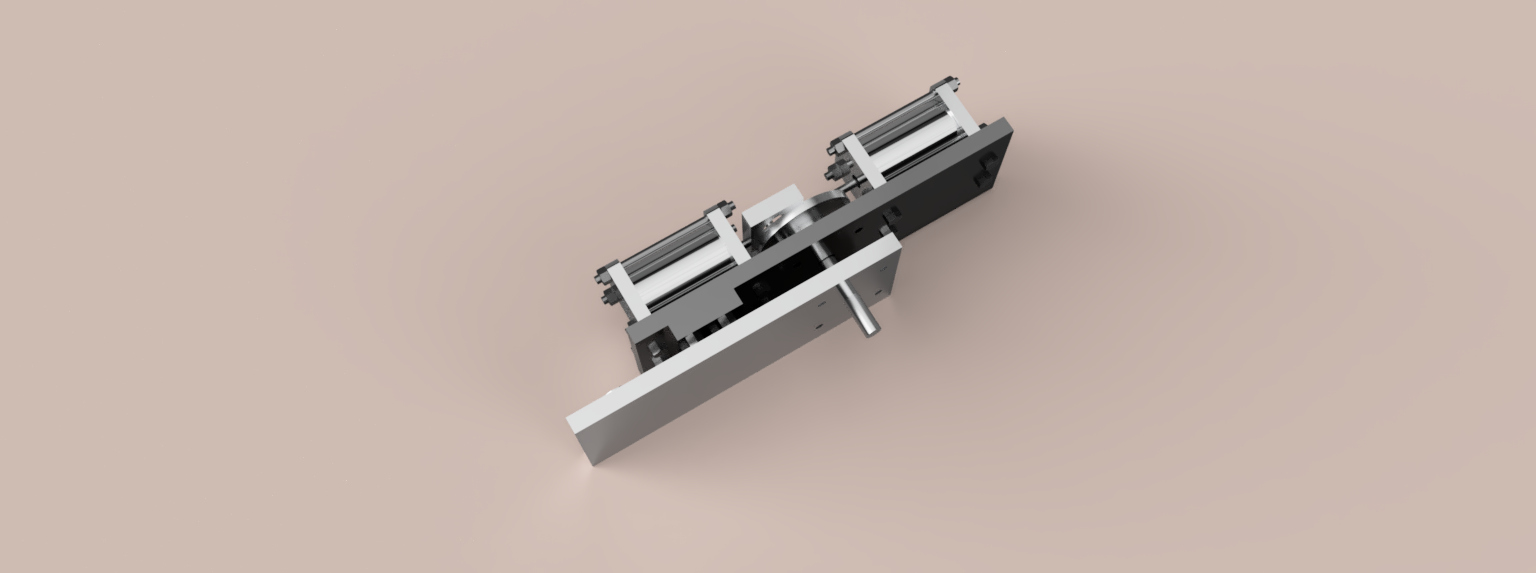

Fabricated Pump

The completed pump assembly after machining and component integration.

Assembly Render

Detailed 3D rendering showing the complete pump assembly and mechanism.

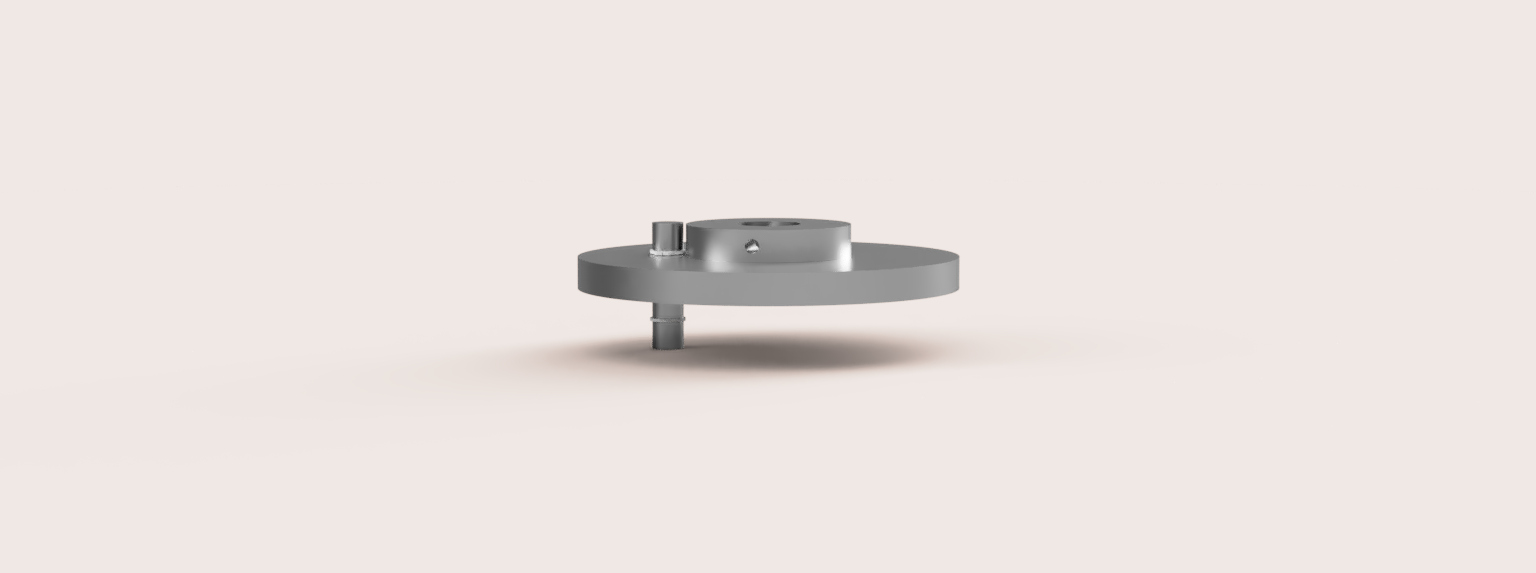

Scotch Yoke Mechanism

Close-up of the precision-machined scotch yoke that converts rotational motion to linear motion.

Engineering Insights & Reflections

Technical Challenges

- Scotch Yoke Fabrication: The precision required for the scotch yoke mechanism was the most challenging aspect of fabrication, requiring careful lathe work to achieve the necessary thickness and smooth operation.

- Sealing System: Ensuring proper sealing at the piston-cylinder interface to prevent leakage while maintaining low friction for efficient operation.

- Alignment: Maintaining precise alignment between the dual cylinders and the drive mechanism to ensure smooth operation and prevent binding.

Engineering Principles Applied

- Fluid Mechanics: Applied principles of fluid flow, pressure, and volume relationships to determine optimal cylinder dimensions.

- Kinematics: Used mechanical motion principles to design the scotch yoke mechanism for converting rotational to linear motion.

- Materials Science: Selected appropriate materials and surface finishes for components based on their mechanical properties and interaction with water.

- Manufacturing Processes: Applied knowledge of machining capabilities and limitations to design parts that could be efficiently fabricated.

Professional Development

Beyond the technical skills developed, this project provided valuable experience with professional engineering practices including:

- Working effectively in engineering teams with delegated responsibilities

- Developing formal documentation including bills of materials and design specifications

- Managing a project through its complete lifecycle from concept to functional product

- Communicating technical concepts and design decisions across team members

- Balancing theoretical design with practical manufacturing constraints

Interested in more projects?

Check out my other mechanical engineering and design work

View Portfolio